If you want to learn about Metal Powder Sintered Filter Elements and choose the style that suits you, then you definitely can’t miss this Blog!

(1)What is a metal sintered filter element

(2)Advantages

High heat resistance: Metal sintered filters can work in high-temperature environments and are suitable for various harsh working conditions.

Strong impact toughness: Compared with traditional non-metallic filters, metal sintered filters can withstand higher working pressure, reducing the risk of damage.

Renewability: The metal material allows the filter element to be repeatedly cleaned and reused, reducing maintenance costs。

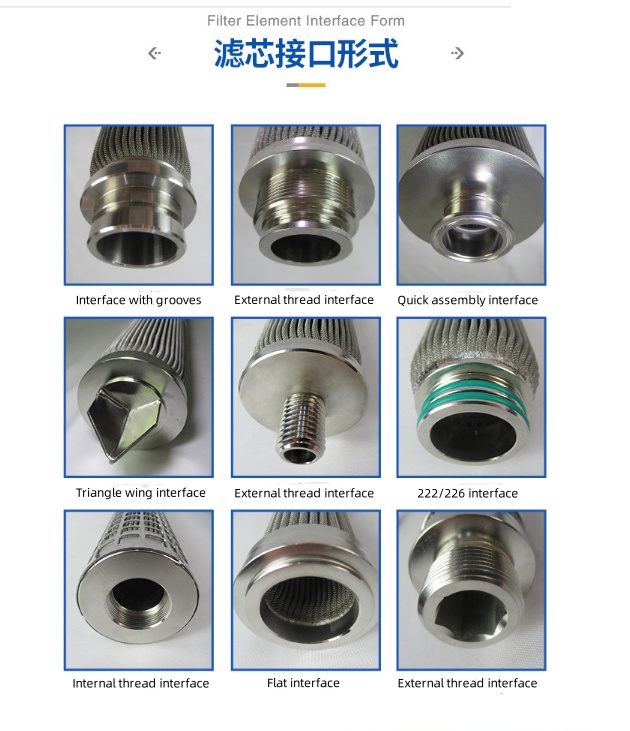

(3)Common interface modes

1. DOE (Double Open)

2. 220

3. 222

4. 226

5. Threaded connections (NPT, BSP, G, M, R)

6. Flange connections

7. Tie rod connections

8. Quick-connect fittings

9. Other customized connections

(4)Application range

1. Catalyst filtration;

2. Filtration of liquids and gases;

3. Mother liquor recovery filtration in PTA production;

4. Filtration in food and beverages;

5. Boiling vaporization bed;

6. Liquid filling tank bubbling;

7. Fire resistance and explosion isolation;

8. Balancing and damping air flow;

9. Probe protection for sensors;

10. Filtration and silencing in pneumatic equipment;

11. Fly ash treatment;

12. Gas homogenization and pneumatic conveying in the powder industry, etc.

Our company, Xinxiang Tianrui Hydraulic Equipment Co., LTD., offers a wide range of powder-sintered filter elements. We can customize production according to customer requirements. Our products are of guaranteed quality and are sold to Europe, the United States, Japan, South Korea and other regions all year round

【For more details, please contact us at jarry@tianruiyeya.cn】

Post time: Sep-12-2025